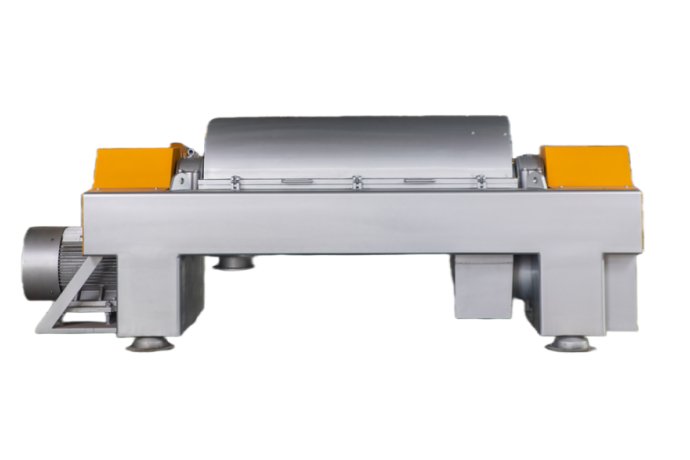

Horizontal Decanter Centrifuge

Our Service

- Offering CAD or 3D drawing services.

- Schneider or Siemens control system with multi-language display.

- Comprehensive and prompt pre-sales, in-sales and after-sales services.

- Providing professional advice on the optimal application methods of the horizontal decanter centrifuge production process.

Description

The horizontal decanter centrifuge is highly acclaimed for its efficient centrifugal separation. During operation, both the drum and screw rotate at high speed in the same direction. As material enters through the screw feed tube, it swiftly accelerates into the drum. Driven by centrifugal force, the heavier solid-phase material deposits on the drum wall. The screw conveyor then propels the solid phase towards the drum’s conical end, facilitating discharge through the slag discharge port. Concurrently, the lighter liquid phase forms an inner ring, overflowing and subsequently discharged through the liquid discharge port, ensuring a seamless and efficient continuous separation.

This centrifuge boasts notable features, such as fully enclosed operation to maintain cleanliness, minimal coagulant and water usage, and a compact layout that minimizes land and infrastructure investments. The machine is designed to achieve continuous feeding, separation, washing, and discharging at full speed, ensuring stable production. It finds versatile applications across various industries, excelling particularly in the separation of suspended liquids with particle sizes above 0.005mm and concentrations ranging between 2-40%. Widely employed in chemical, light industry, pharmaceuticals, food, and environmental protection, it stands as a dependable solution for centrifugal separation.